Shell PANOLIN

Van Meeuwen Lubrication & Shell PANOLIN: Sustainable Lubrication for the Future

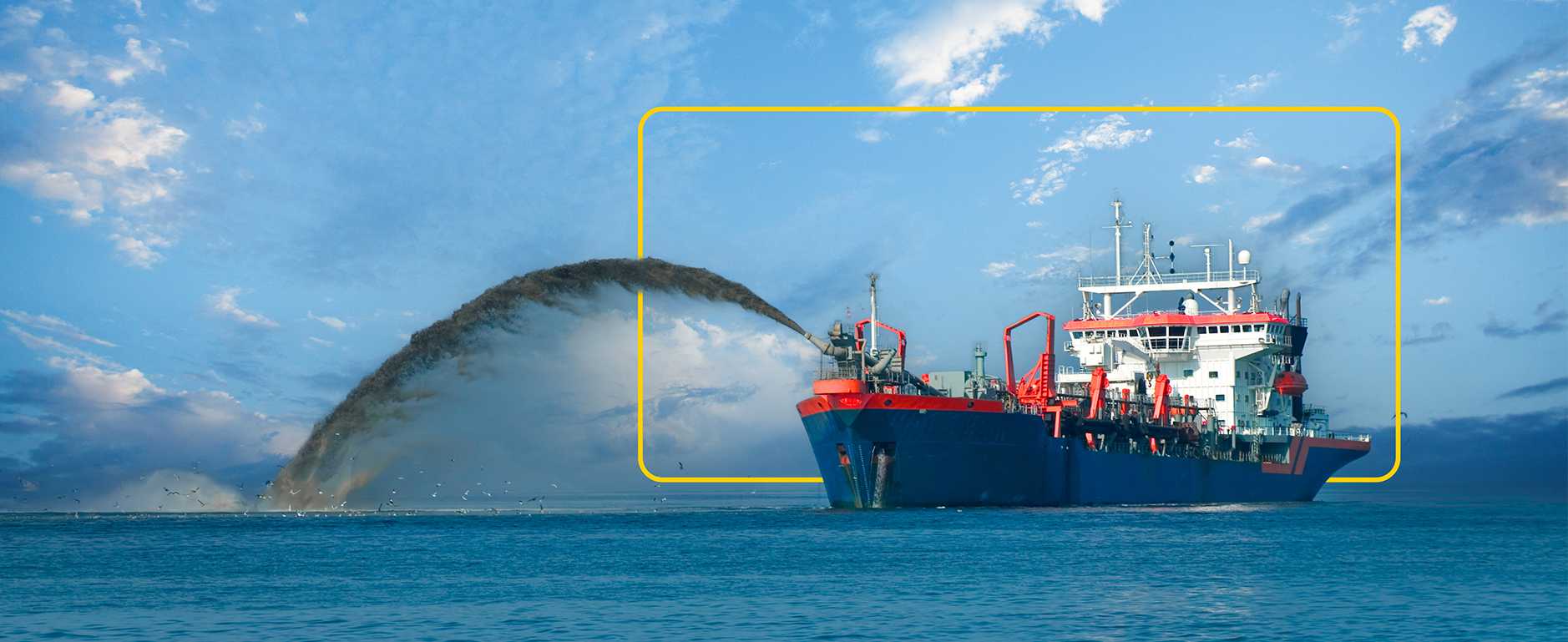

In industries such as maritime and offshore, infrastructure, and construction, sustainable business practices are becoming increasingly important. The use of biodegradable lubricants plays a crucial role in this. Together with Shell PANOLIN, Van Meeuwen Lubrication offers high-quality bio-lubricants that are not only environmentally friendly but also optimize machine performance and reduce costs.

With Shell PANOLIN bio-lubricants, oil change intervals are extended, breakdowns and leaks are reduced, and the environmental impact is minimized—even in the most sensitive environments. At Van Meeuwen, we call this ‘Smarter Lubrication’: the smart and sustainable choice for a greener future.

What Does Biodegradability Mean?

Biodegradability refers to the natural ability of organic substances to be broken down by microorganisms into simpler, harmless substances. The degree of biodegradability indicates how much of a chemical substance remains in the environment over time.

To meet the EAL qualification (Environmentally Acceptable Lubricant), Shell PANOLIN adheres to the OECD 301 B test method. The standard requires that at least 60% of the lubricant must degrade within 28 days. Additionally, the lubricant must not be toxic and should not accumulate in the environment (bioaccumulation).

Lower Consumption, Lower Costs, and Reduced CO2 Emissions

As a specialist in lubrication technology, Van Meeuwen Lubrication sees the quality of environmentally friendly lubricants as crucial to the success of sustainability efforts. That is why we choose high-quality biodegradable lubricants that have proven to perform better than regular bio-lubricants or mineral lubricants.

What are the benefits of bio-lubricants:

- Biodegradable: Over 60% breakdown within 28 days (according to OECD 301 B standard).

- Environmentally Friendly: No bioaccumulation and minimal toxicity, reducing environmental impact.

- Extended Oil Change Intervals: Maintenance intervals extended from 5,000 up to 20,000 hours, leading to less maintenance and reduced downtime.

- Cost Savings: Lower maintenance and replacement costs due to longer operational life and reduced oil consumption.

- Reduced CO2 Emissions: Less oil consumption and longer oil change intervals contribute to a lower ecological footprint.

- Excellent Performance: Suitable for extreme pressures and temperatures, with reliable performance in low-temperature conditions.

Shell PANOLIN S4 HLP Synth E

Shell PANOLIN S4 HLP Synth E is a highly successful, biodegradable hydraulic oil, developed from renewable synthetic esters. This oil performs excellently under extreme pressure. It provides optimal protection against friction and wear, and is suitable for both stationary and mobile hydraulic systems across industries such as earthmoving, forestry, machinery, construction, and hydroelectric technology.

Additionally, Shell PANOLIN S4 HLP Synth E is ideal for compressors, bearing lubrication, oil circulation systems, and hydraulic systems on ships, including CPP, stabilizers, steering gears, and deck equipment. In short, this specific oil is perfect for a wide range of applications.

Key Sectors for the Use of Bio-Lubricants

Bio-lubricants like Shell PANOLIN S4 HLP Synth E are increasingly being used across various sectors, including:

- Hydraulic Systems: Cranes, winches, and other applications on workboats.

- Excavation Work: Both on land and in water.

- Demolition and Recycling Projects: Earthmoving and other related operations.

These sectors benefit from the environmentally friendly properties and high performance of biodegradable lubricants.

Discover how Shell PANOLIN and Van Meeuwen Lubrication can help you optimize machine performance while protecting the environment. Contact us today for tailored advice! Email us at sales@vanmeeuwen.com or call our Sales Department at +31 (0)294 494 494. We are happy to assist you!