Chemicals

Reliable and safe solutions

Downtime is not an option

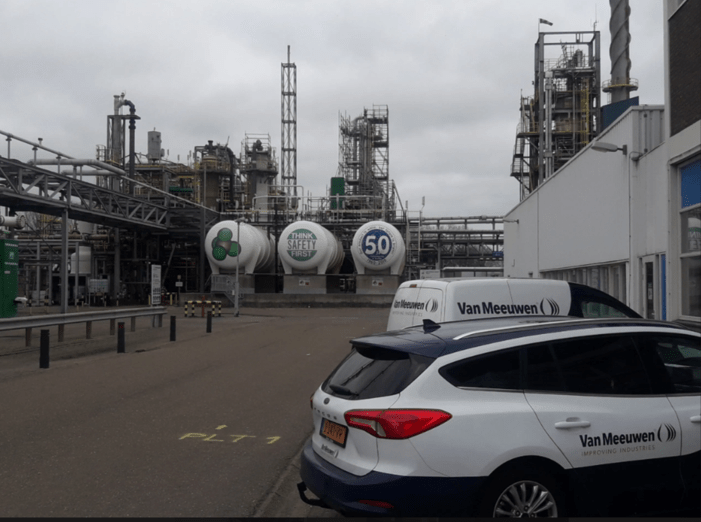

The Dutch and Belgian chemical sector plays a key role on a global level. With a place among the European and global leaders, this sector is the silent force behind around 95 per cent of the products we use every day, from medicines to plastics and packaging. Behind these impressive figures lies one clear need: processes must always continue to run. Continuity, safety and reliability are crucial. This is precisely where the importance of smart and careful lubrication maintenance comes in.

Lubrication tailored to the chemical sector

Safety and reliability do not come naturally; they are the result of using the right materials in the right place. That is why our lubricants have been specially developed for the petrochemical and chemical industries. They meet the most stringent requirements and are chemically resistant, non-toxic, non-flammable and non-corrosive.

These powerful lubricants perform optimally even under extreme pressure and temperatures. Where necessary, they are chemically inert or fully tailored to the materials used in the processes. In this way, they offer maximum protection, extend the service life of installations and contribute to sustainable production.

24/7 reliability and safety as standard

In an industry where every minute of production counts, downtime is not an option. Machines and installations must continue to operate smoothly, day and night, without posing any risks to human safety or the environment. Lubrication maintenance plays a crucial role in this. It prevents unexpected breakdowns, facilitates planned downtime and ensures that processes always continue to run as planned.

By having lubricants checked and analysed regularly, you can detect wear at an early stage and prevent unexpected machine downtime. This keeps your processes reliable and prevents unexpected costs. What’s more, it ensures a safe working environment that you and your team can rely on with confidence.

Sustainable maintenance starts with smart choices

By opting for smart and preventive maintenance, you not only ensure greater safety but also minimise your environmental impact. Fewer breakdowns and fewer replacements mean less waste and a more efficient use of raw materials. This way, you benefit as a company and contribute to a more sustainable world.

More information?

Want to be sure that your lubrication maintenance is optimally organised? Contact our specialists for customised advice, inspections and analysis. Together, we will ensure that your processes continue to run safely, reliably and sustainably, today and tomorrow.