Van Meeuwen Lubrication

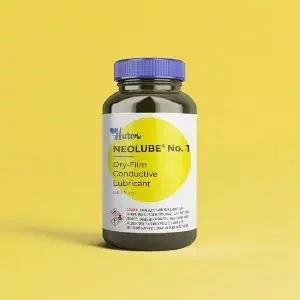

NEOLUBE®

Resistant to radiation

NEOLUBE® lubricants have the unique property of being highly resistant to nuclear radiation. They are high-performance lubricants with very high chemical purity and low halogen content. They consist of exceptionally stable compounds of colloidal micrographite and thermoplastic resin in isopropanol. NEOLUBE® lubricants cannot migrate or freeze.

The coating is easily applied during manufacture or assembly to form an ultra-thin opaque film using brushes, sprays or dipping. This coating dries in seconds to form a smooth, shiny, non-corrosive, dry and adhesive lubricating film of the purest graphite. This makes it ideal for lubricating metal parts with limited clearance.

NEOLUBE® lubricants

NEOLUBE® lubricants are available in various versions: NEOLUBE® No. 1 and NEOLUBE® No. 2. In addition, there are two industrial pipe thread sealants: NEOLUBE® Pipe Thread Sealant No. 100 (max. 300°F = 149°C) and NEOLUBE® No. 1260 High-Temperature Sealant and Lubricant (max. 1175°F = 635°C).

NEOLUBE® No. 1

NEOLUBE® No. 2

Qualified Products Lists

NEOLUBE® lubricants are manufactured by the American company Huron Industries, Inc. and have been listed on the QPL (Qualified Products Lists) for this product since 1974. The following National Stock Numbers are associated with NEOLUBE® No. 1.

- 9150-00-926-8963

- 9150-01-304-6633

- 9150-LL-L12-5267

- 9150-LL-S04-5217

- 9150-01-335-5044

- 9150-LL-HX6-3358

- 9150-00-LL-N91-0354

- 9150-LL-RM1-3003

- 9150-01-499-2121

The differences and benefits

NEOLUBE® No. 1 and NEOLUBE® No. 2 are both conductive dry lubricants that are frequently used in nuclear power plants and other nuclear installations as anti-seize lubricants for screw threads and for lubricating moving parts and rubbing surfaces. The very thin coating is wear-resistant, offers optimum resistance to abrasive wear and facilitates assembly and non-destructive disassembly.

NEOLUBE 1 and 2 are not recommended for lubricating threads in the primary sections of the reactor where temperatures exceed 400°F (=204°C) and in an oxygen environment. However, it is recommended for use in the secondary sections of a reactor and has been used successfully in applications where radiation levels of 1 x 109 rads prevail.

The difference between the two versions is that NEOLUBE No. 1 meets the stringent requirements of military specification MIL-L-24131C: it therefore complies with the strict requirements for the lubrication of the internal and auxiliary equipment mechanisms of commercial and marine nuclear reactor systems.

NEOLUBE® applications

- As an anti-seize lubricant on bolts, nuts and valves

- On stainless steel bolts for nuclear applications under MIL-L-24131C

- As a dust-free lubricating film for machines, clocks, locks, piano and organ mechanisms

- As a lubricant for valves in hydraulic installations

- As a lubricating film on electrical contacts and electrode contact shoes to prevent burning and pitting

- As a lubricant for chains that operate at high temperatures and where dirt adhesion must be prevented

- As a coating to prevent the formation of rust

- As a dry lubricant for machining operations

- As a lubricant in the textile industry on knitting and weaving machines

- As a coating for moulds

- For use in vacuum systems

Would you like to know more?

Curious about what we can do for your organisation in the field of lubrication technology? Please feel free to contact us at +31 (0)294 494 494 (NL) or +32 (0)53 76 76 00 (BE) or send an email. We are happy to contribute ideas and assist you further.