Packaging

Anti-static

Reliable anti-static additives

Static charge is not only undesirable during the production process, but you also don’t want static charge from the packaging itself. In production, static charge causes quality problems and annoys consumers when packaging containing (electronic) products attracts unwanted dust. Our anti-statics prevent these annoyances.

Our food-safe anti-static additives prevent static charge and promote controlled discharge. For a smooth-running process and a better user experience. Because details make all the difference.

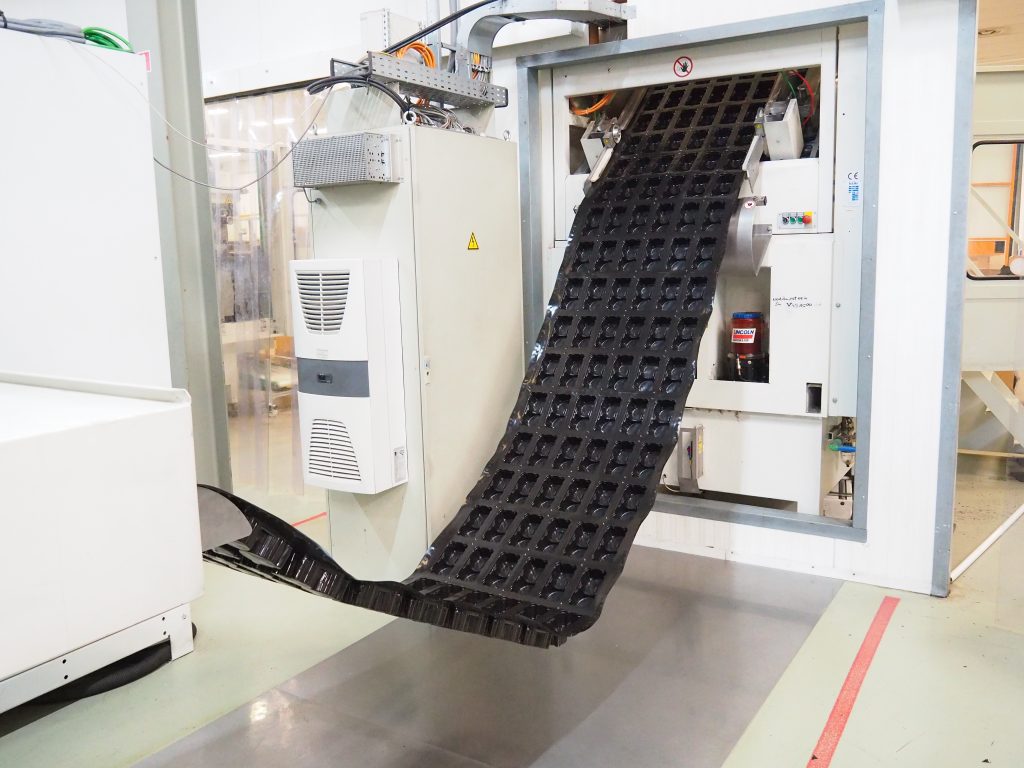

Anti-static for plastic sheeting

The static charge of plastic sheets can interfere with your process. Creating collaborative solutions for your production and packaging is what Van Meeuwen stands for. With anti-static coatings, we ensure that the static charge on the sheet remains completely under control.

This phenomenon often occurs when the humidity is low. This can attract dust from the environment. In some cases, this can even create a hazardous situation, such as when extruding polystyrene sheets, where an electric shock can occur during the production process.

Van Meeuwen helps you create a clear sheet that is less sensitive to static charge, keeping both your customers and your production team happy.

Where are our anti-static additives used?

Anti-static additives are used to prevent negative effects and electrostatic charge.

They reduce dust attraction, printing ink splashing and prevent static discharges or shocks on machines during processing.

The anti-static additives have been specially developed for non-conductive materials such as plastics (polyester, polystyrene) and mineral glass wool. Important: they are effective immediately after treatment and are not affected by humidity.

If there are any special challenges, we always develop a customised solution.

The benefits of anti-static coatings for plastics

Our anti-static additives prevent static charge and promote discharge, resulting in excellent conductivity and fast discharge time.

The effect is independent of relative humidity. Our products are water-soluble and effective at low concentrations. Often, only a small amount is needed within the production process.

In addition, we work exclusively with low-toxicity materials that are immediately effective after application.

The coëfficiënt of friction (CoF) can be reduced even further in combination with our anti-block additives.

Food safety and registration

Our Baxiline AS and FOODCARE® additives comply with European Regulation (EU) No. 10/2011 of 14 January 2011 and subsequent amendments concerning plastic materials and articles intended to come into contact with food. The products we use have the appropriate registrations. If you have any questions about this, we will be happy to help you.

How does static charge work?

Most plastics are very good insulators, with very low electrical conductivity.

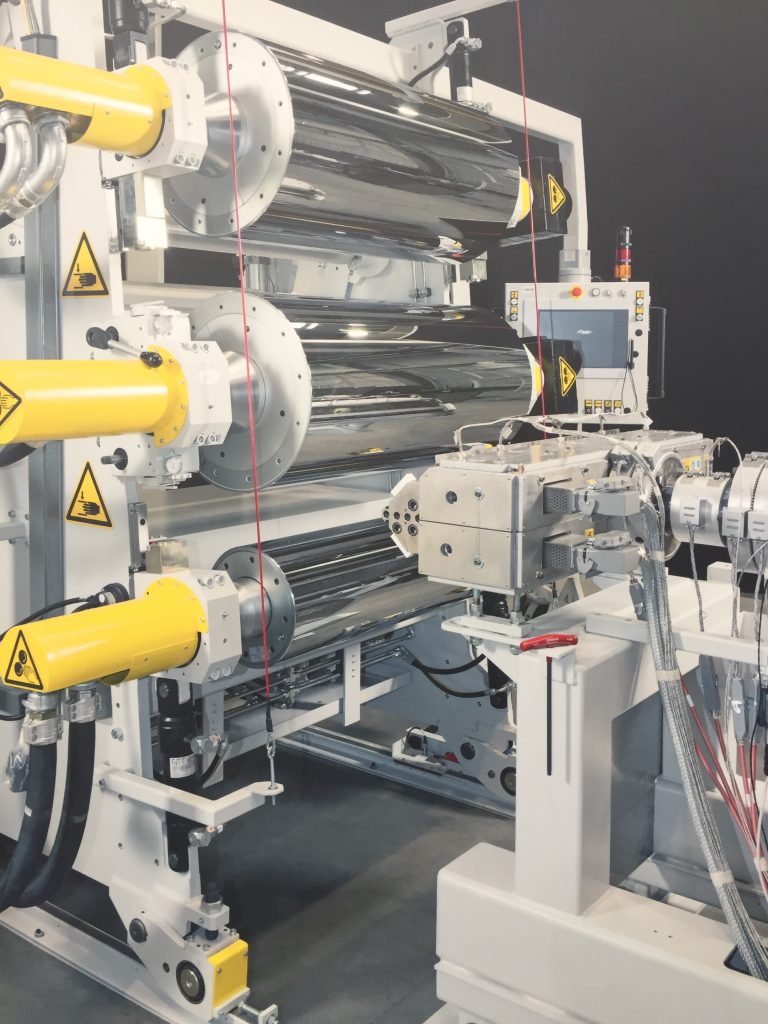

In order to dissipate the charge, the anti-static additive forms a conductive film or coating on the surface. The result: excellent conductivity and fast discharge time on the surface. Our specialty fluids are ideal for coating stations such as rotor spray systems and kiss-roll applications.

Using anti-static coatings

Our anti-static additives are concentrated water-based solutions and must be diluted before use. These special fluids are applied via coating stations such as rotor spray systems and kiss-roll applications. They can be combined with a (modified) silicone emulsion to improve the hydrophobicity and friction (CoF) of the surface.

Would you like to know more?

Curious about what we can do for your organisation? Please feel free to contact us at +31 (0)294 494 460 or send an email. We are happy to contribute ideas and assist you further.